On a lonely plateau in the wide-open spaces of the Intermountain West, the Western Quonset Lodge is taking shape.

This has been an extremely challenging project on many different levels, and it’s a real tribute to my client’s vision and fortitude that he has hung in there and seen it through to construction.

Overall, the project consists of a two bedroom, two and a half bath home, with living all on one level and an open loft above. Also housed within the main XQ45-model home is an attached garage with a large open workshop space above it, adjoining the open loft. Across the driveway is a second, smaller Quonset hut workshop space.

Above: in the foreground you can see the formwork for the workshop’s foundation; beyond is the prepped area for the house’s foundation. You can see the Quonset huts stacked on their palettes in front of where the garage doors will be. At the far end of the house will be the dramatic front porch shown in the rendering at the top of the post, looking out towards the mountains, off in the distance.

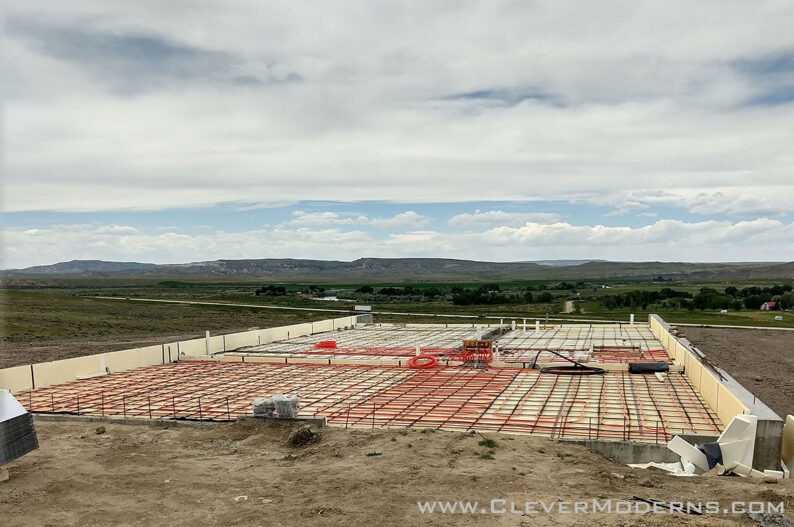

Below: looking from the garage doors across the ground floor of the house, which is in the process of being prepped for the floor slab pour. The arch will be set up on a 1′ high curb which has already been poured, and you can see the white insulation board placed along the curbs on each side. The vertical insulation board will create a thermal break between the heated floor slab and exterior concrete.

Above (sorry it’s a little blurry) you can see the finished floor slab with the considerable number of hydronic tubing ends sticking up in the middle, which will be in the utility room between the garage and kitchen. The rectangular depression in the slab at the right middle area will be for the shower floor.

Arches up! The hut is by SteelMaster and is 45′ wide by about 20′ tall. This is a custom size.

I generally counsel my clients to avoid side windows if possible, but in this case Mr. Client really wanted them, and made a good case for using them. (And in case you haven’t noticed, he is definitely adventurous and up for a challenge!) I came up with some special details that should work well and keep the long term maintenance relatively straightforward.

Figuring out the big front porch canopy and working out all the technical specs for it was quite a process, involving a structural engineer with expertise in timber framing, plus SteelMaster’s factory engineering team. It became pretty clear early in the process that SteelMaster was the only Quonset hut manufacturer out there who could handle this type of unusual architectural use of the Quonset hut panels.

Congrats to my clients on this major milestone!

Curious about Quonsets? Ready to learn more about these bizarre, amazing, shiny, round, prefab structures? Drop your info below and I’ll start you off on my email tutorial series. Looking to build an inexpensive but beautiful home debt-free? Considering going off-grid? Or are you just tired of the same old same old and want something unique and beautiful? A Quonset House might be the answer for you.

Follow us on Instagram and Facebook. We also have a private Facebook group called DIY Quonset Dwellers, where we share discussion, design, and construction tips with others who are interested in building their own Quonset hut house. With over 6,000 members and counting, the Facebook group has grown into an amazing resource all of its own! Learn more and request to join the Facebook group here.